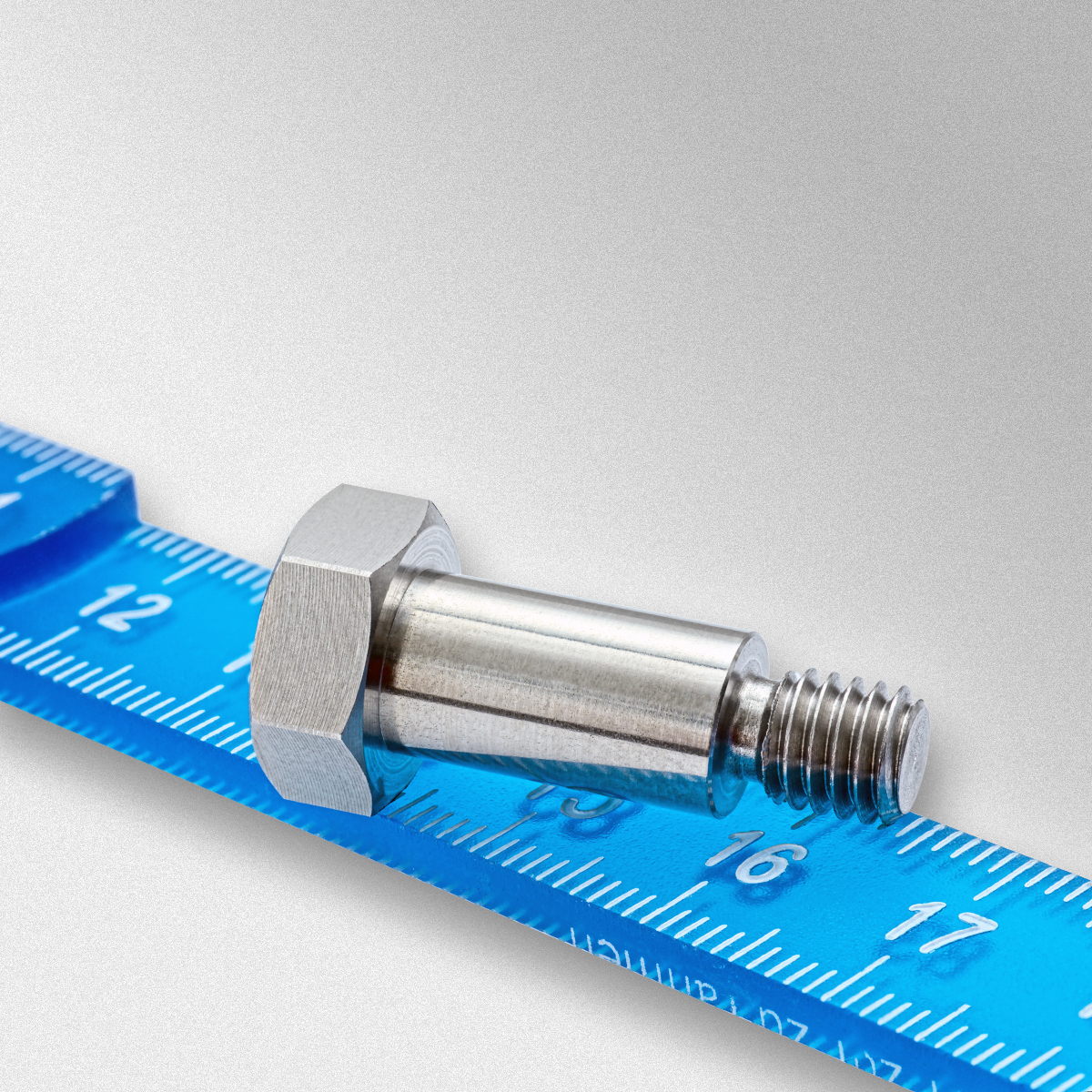

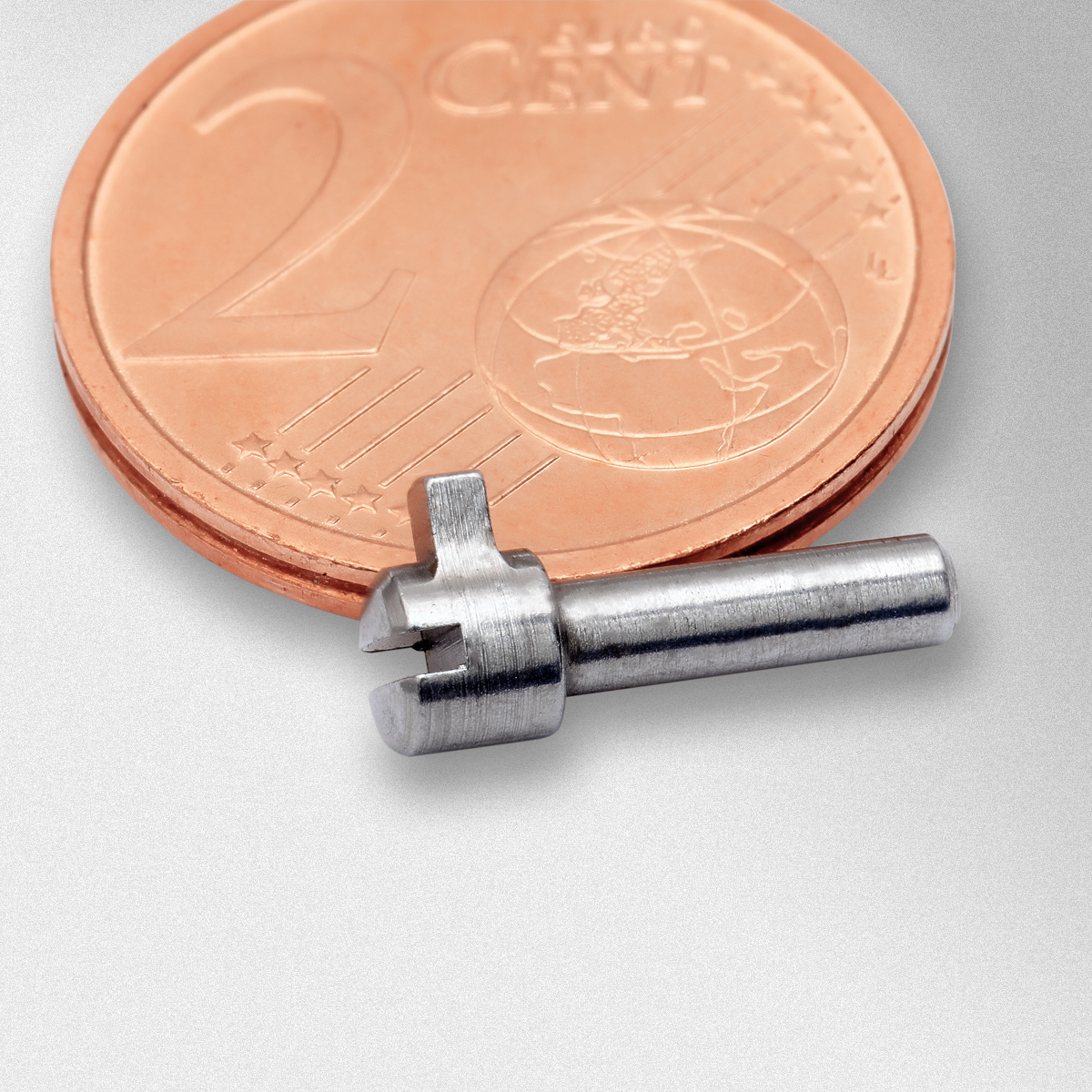

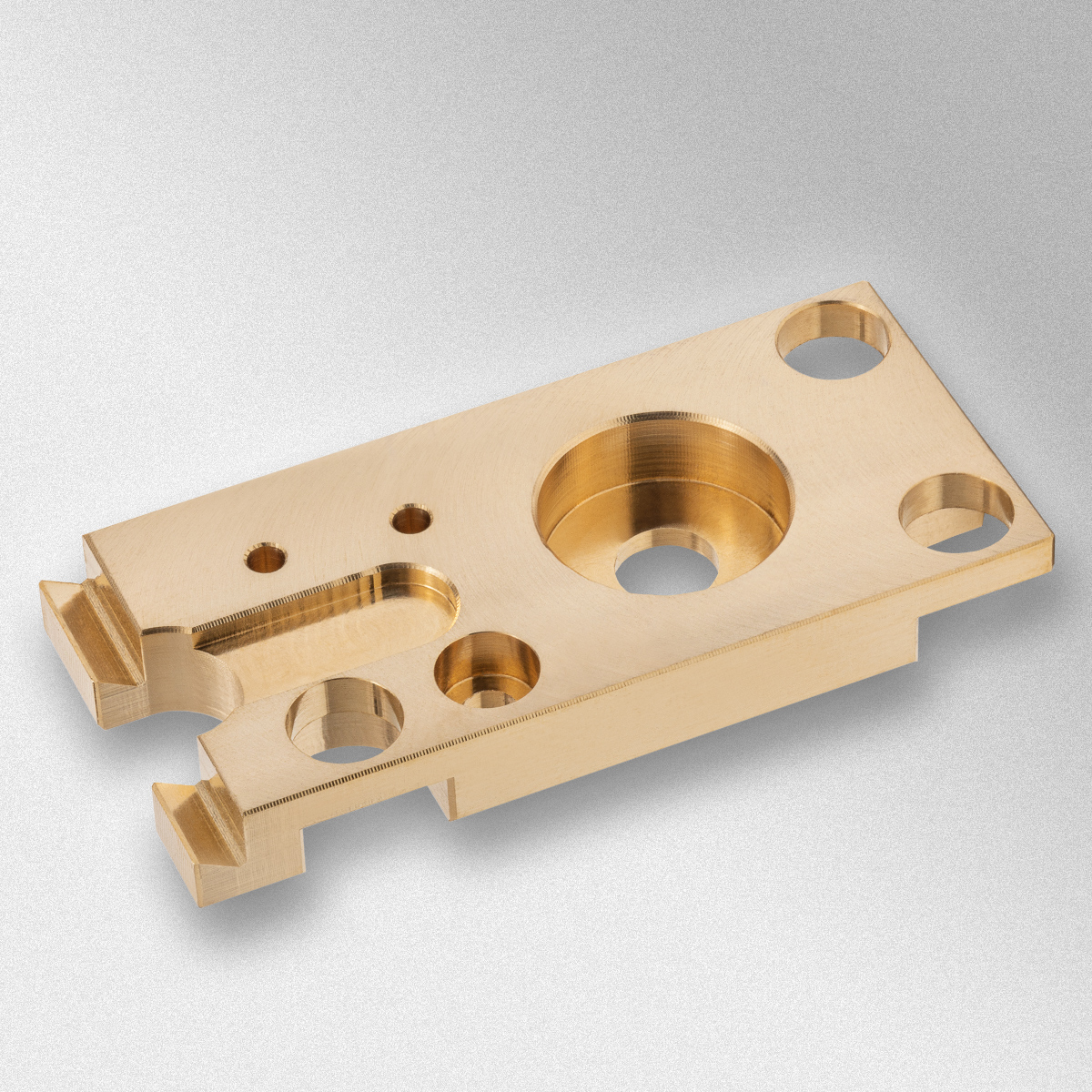

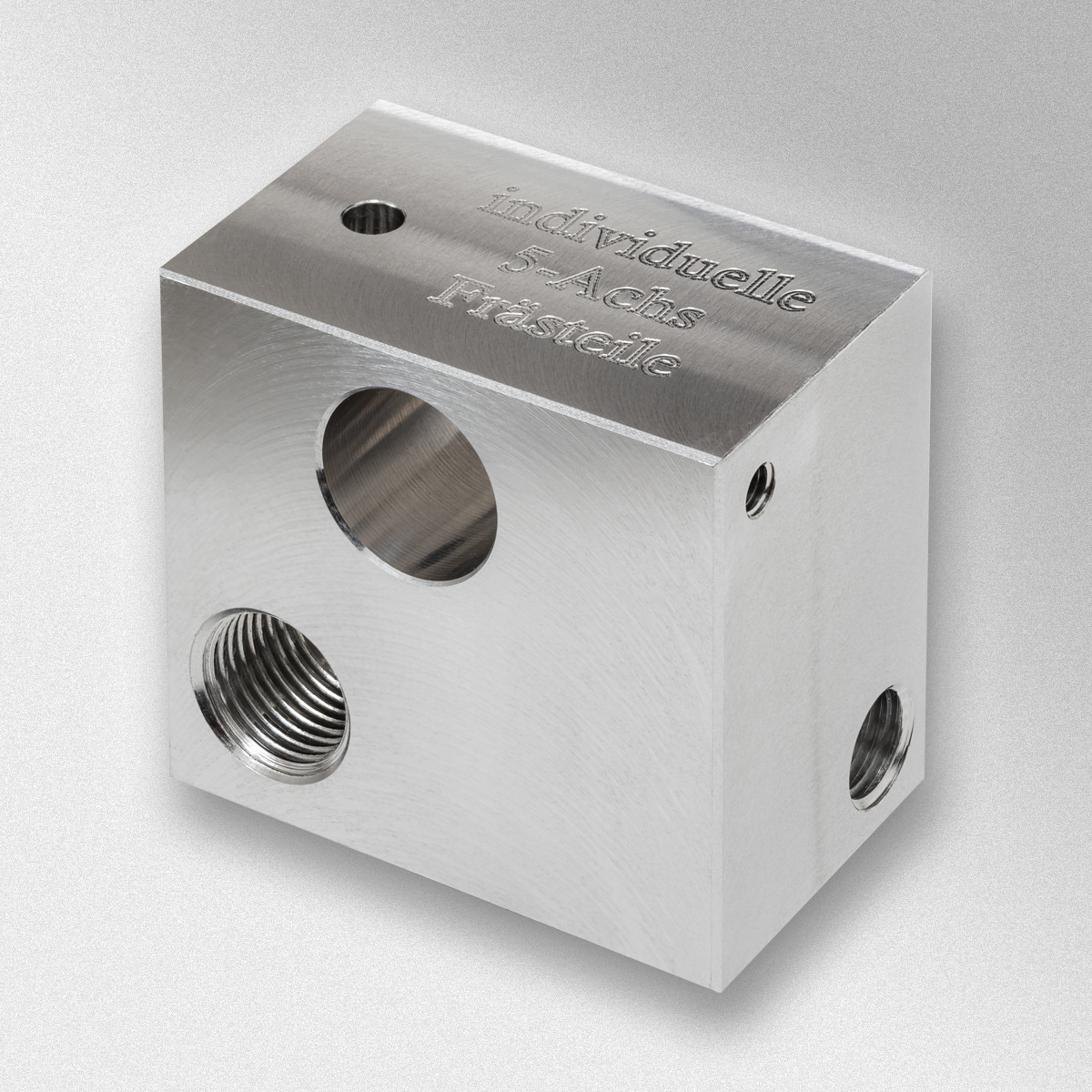

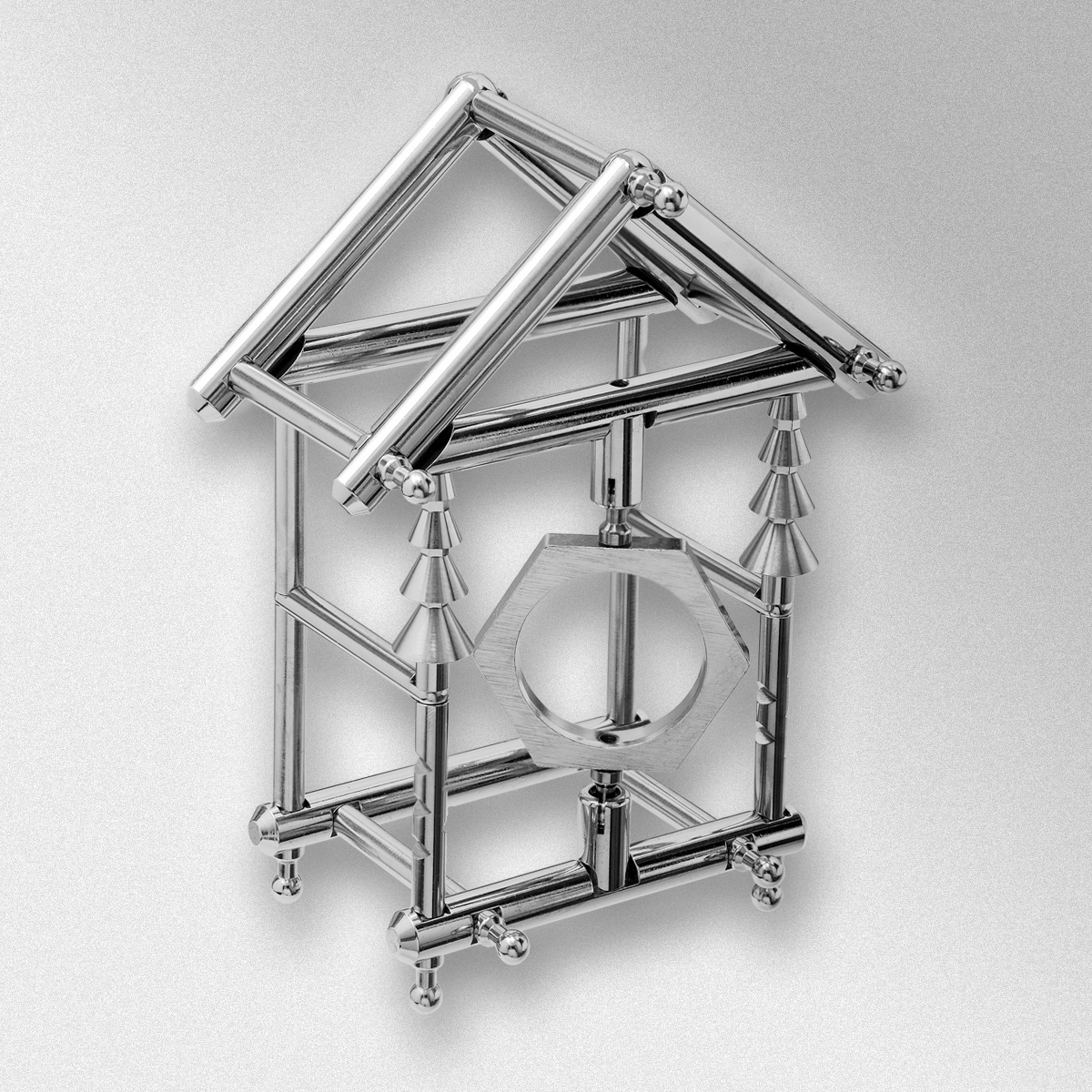

Turned parts with complex contours

The production of CNC, fine and precision turned parts with complex contours is all part of our everyday work. We manufacture approx. 5000 different CNC and Swiss turned parts from all materials in sizes ranging from one to 26 millimetres in diameter.

We use the latest CNC technology, enabling us to produce complex product contours for our customers without costly moulding tools. Our high level of vertical integration allows us to react to individual customer requests and changed machining specifications in the shortest possible time.

We manufacture from a batch size of approx. 200 pieces. We strive to offer the highest manufacturing quality with prompt order processing.